Custom Insert Molds

CDM Tool & Manufacturing designs and manufactures custom-insert molds for plastic injection molding. Insert molds allow the integration of additional components like metal inserts or other pre-formed parts into the final molded product. With over six decades of mold design and manufacturing expertise, you can rely on CDM to create precise insert molds with industry-best tolerances.

Contact us today for high-performance, customizable insert molds.

What isInsert Molding?

Insert molding is an advanced plastic injection molding technique where additional components are integrated into the plastic mold during a single molding cycle. Pre-formed parts and metal inserts can be integrated into plastic molds to enhance a product's functionality and structural integrity. CDM excels in designing and manufacturing insert molds, guaranteeing seamless integration of diverse materials for superior plastic injection molding.

Insert Molding Advantages:

- Enhanced durability

- Increased functionality

- Improved dimensional precision

- Reduced material waste

- Created in a single molding cycle

Hire an Experienced Insert Mold Designer

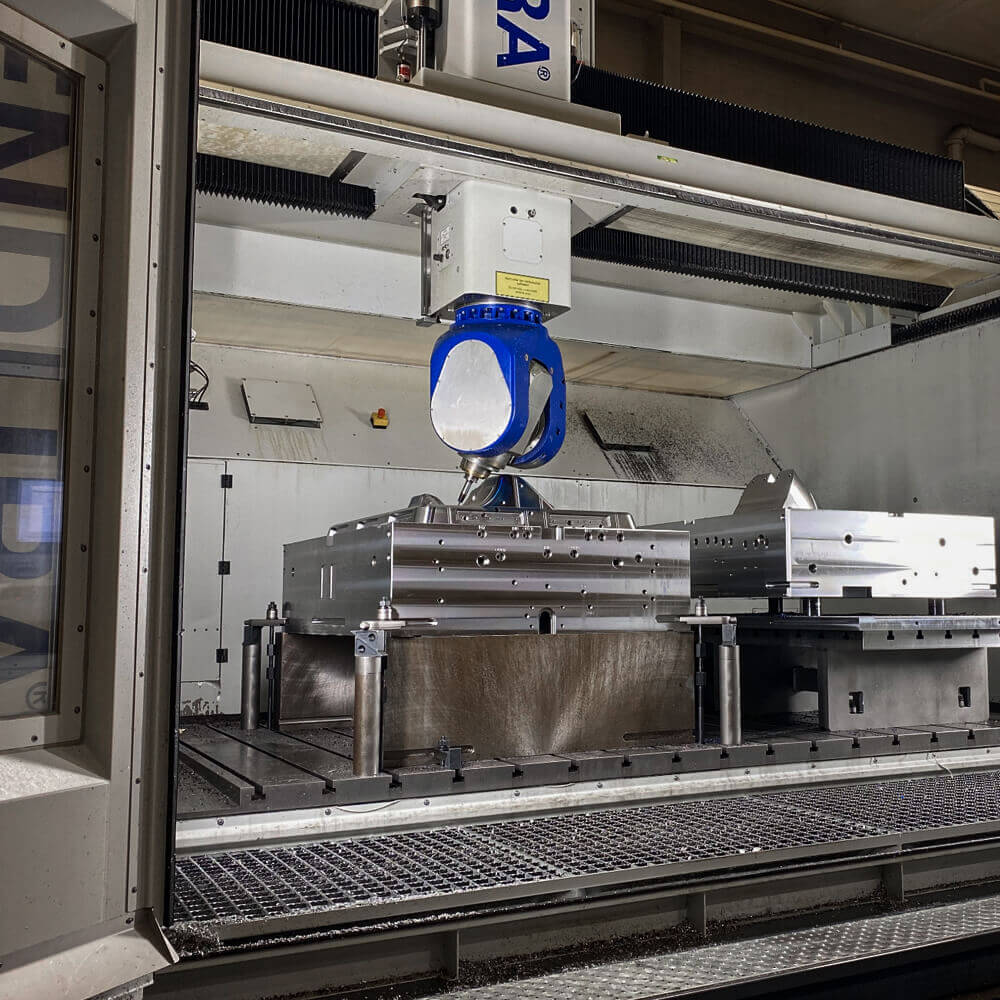

Insert mold design and manufacturing require high design expertise and precise equipment. CDM Tool & Manufacturing’s team of expert injection mold design specialists use state-of-the-art tools to manufacture the industry’s best molds. From CAD files to blueprints or specifications - we bring innovative ideas to life.

Custom Insert Mold Design Process

At CDM Tool & Manufacturing, our custom mold design process is meticulously tailored to meet each client’s needs. With over 60 years of industry experience, we transform your ideas into precision-engineered insert molds. Our expert design team collaborates closely with you, providing valuable feedback on part designs and addressing complexities for optimal performance. We utilize advanced CAD modeling and consider critical factors like material options, tolerances and manufacturability throughout the design phase.

Our commitment to excellence means every mold we create is precisely crafted using state-of-the-art software tools like Siemens NX. This meticulous approach enhances production efficiency and guarantees high-quality results and seamless integration with your specifications. Experience the difference our design expertise can make—contact us today to discuss your custom insert mold project!

Applications for Insert Molding

Insert molding is a versatile manufacturing process with applications across multiple industries. At CDM Tool & Manufacturing, we specialize in creating custom insert molds tailored to meet the specific needs of various sectors. Here are some key applications:

- Automotive: Insert molds help create components with enhanced strength and durability like brackets, housings and connectors.

- Medical: In the healthcare industry, insert molding produces precision parts like surgical instruments and housings for medical devices.

- Electronics: The integration of metal inserts into plastic housings improves the functionality of electronic components, promoting better performance and longevity.

- Consumer Products: From household appliances to sporting goods, insert molding allows for innovative designs.

- Industrial Equipment: Insert molds are used to make parts with added strength and resistance to wear, making them ideal for various industrial applications.

With our expertise in insert mold design and manufacturing, CDM Tool & Manufacturing delivers high-quality solutions tailored to industry demands.