Custom Complex Action Molds

CDM Tool & Manufacturing expertly designs customized complex action molds for plastic injection molding. Complex action molds are sophisticated, multifaceted tools created through a single molding cycle to streamline production and reduce overall costs. Our 60+ years of experience in the mold manufacturing industry equips CDM to create complex action molds with the utmost precision and strictest tolerances possible.

Contact us today for complex action molds with unparalleled functionality and performance.

What is Complex Action Molding?

Complex action molding is a plastic injection molding process in which a single cycle creates a multi-dimensional mold with moving components. This specialized process excels in crafting items ranging from precise, small-scale elements to larger intricately shaped parts with multifaceted design attributes.

Complex Action Molding Advantages:

- Created in a single molding cycle

- Increased geometric precision

- Reduced need for assembly and post-processing

- Low material waste

- Highly flexible and durable

Hire an Experienced Complex Action Mold Designer

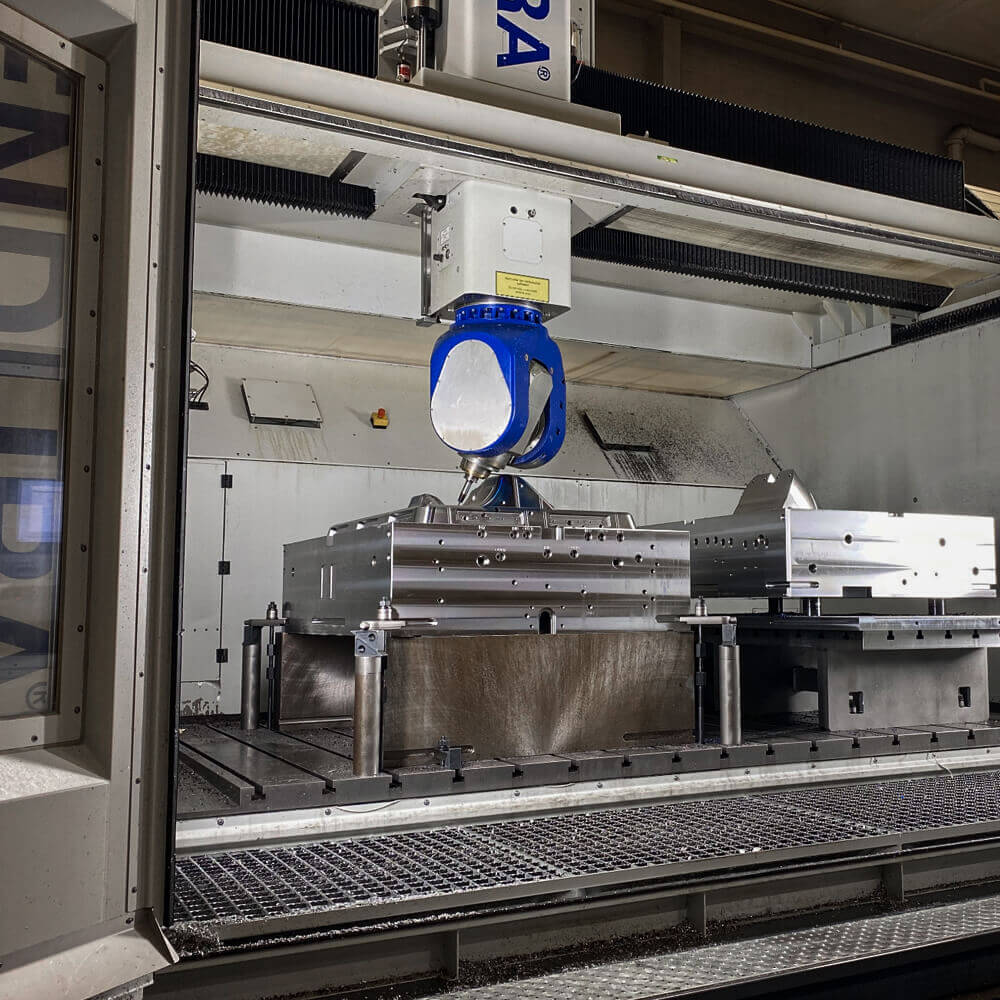

Complex action molds require a higher level of design and more precise equipment than a standard plastic injection mold. CDM Tool & Manufacturing’s injection mold technicians combine the industry’s best tools with expert design solutions to create the best molds available. From CAD files to blueprints or specifications - we bring innovative ideas to life.

Precision Manufacturing of Custom Complex Action Molds

CDM Tool has a history of providing companies with extremely precise molds, which is where we separate from the pack. We produce molds with tolerances down to 0.0006 over a 140-inch span and 0.0014 over a 23-foot span. Other shops boast their abilities, we prove ours with our work.

Contact us today for a quote on complex action molds machined to your exact specifications.

Common Applications for Complex Injection Molds

Complex action molds are essential across various industries for the production of intricate components:

- Agricultural: Irrigation system components and machinery casings with UV-resistant properties for outdoor use.

- Transportation: Dashboard panels and door handles combining functionality with sophisticated design in automotive applications.

- Medical: Surgical instruments and drug delivery systems requiring high precision for safety and efficacy.

- Construction: Fasteners, connectors and fittings demanding durability and complex shapes.

- Automation: Control panels and housings for industrial equipment prioritizing strength and detailed design elements.

- Electrical: Connectors and device housings supporting compact and efficient designs in consumer electronics.

- Hardware: Power tool housings emphasizing durability and user-friendly features.